Just In Time and Sequencing

Just In Time and Sequencing

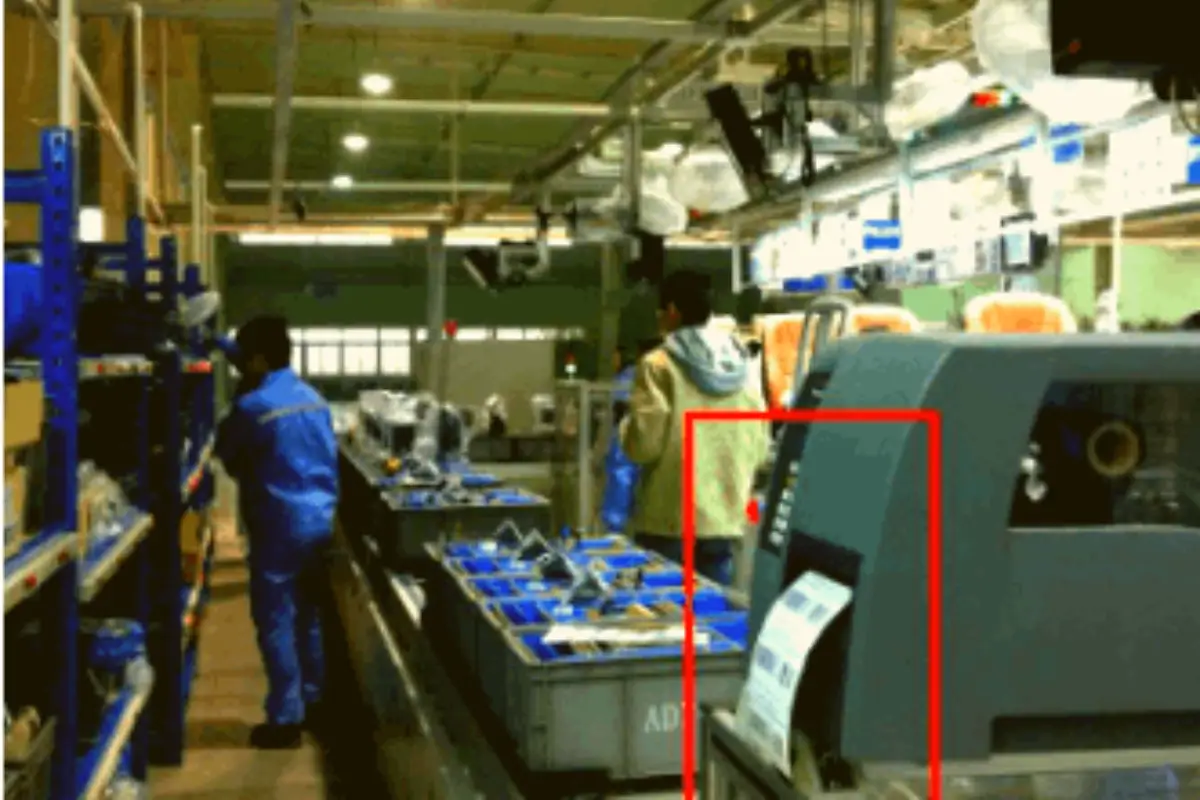

Most ERP systems do not provide any functionality to drive the shop floor operations, leaving an increasing gap in the IT application stack. Our Shop Floor Management System is designed to fill the gap between SCADA process control systems and ERP systems. Our software systems can help you achieve operational excellence on the shop floor.

DEMAND RECEIVING & PROCESSING

PRODUCTION SCHEDULING

SERIALIZATION & LABELLING

LINESIDE INVENTORY

MONITORING

ERP INTEGRATION

TRACE DATA & GENEALOGY

PACKAGING & SHIPPING

JIT Sequencing

JIT Sequencing is

- An ERP agnostic stand alone shop floor system

- A flexible and configurable solution for many business scenarios

- An Open Systems Architecture based application for enhancements and integration.

Automotive Sequencing

We have an extremely strong, proven track record with Tier 1 Automotive components suppliers who supply on a JIT basis using a multitude of JIT practices such as sequence supply, Kanban, Pickup Sheets etc.

Our systems support the stipulations of OEMS such as BMW, VOLVO, Daimler, Tesla, Ford, Chrysler, Toyota, Mitsubishi, Honda, Nissan, KIA, Hyundai, FIAT, Opel and PSA.

You will find full technical details of our solution in this brochure and our sales team is available for all your questions.

Embark on your journey

towards digital transformation

Learn More About Lean

Download Brochure

Driving 50+ Factories in the Automotive Supply Chain

Industry 4.0

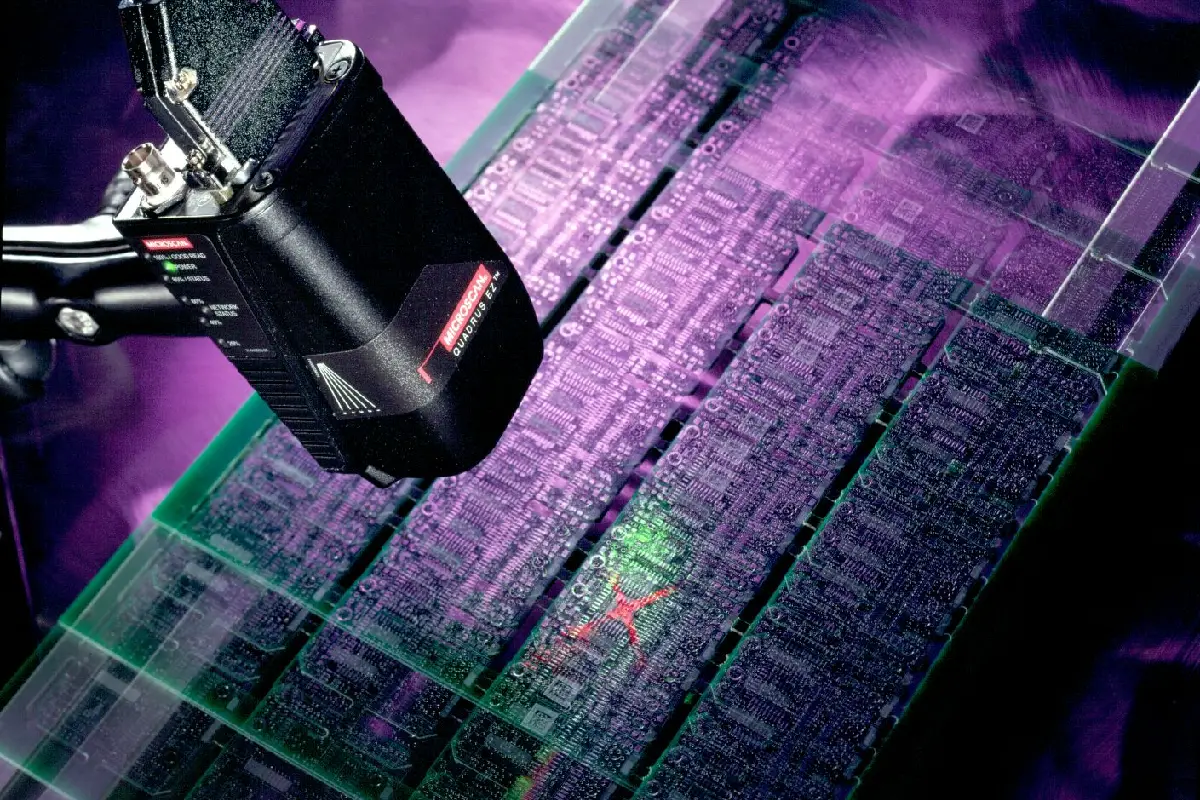

Lack of an open flexible MES platform is one of the biggest hindrances to adopting Industry 4.0. Easy Manufacturing has been built using a modern open systems architecture making it the most ideal foundation for Industry 4.0. The architecture allows for specialist modules/applications such as Vision Systems and Robotics systems to be easily integrated and exchange information with the MES system.

Deployment

Easy Manufacturing can be deployed On Premise or in the Cloud. he system has a HTML5 User Interface that can run on any tablet/PC. The disconnected architecture allows for small networking outages and hence production will not be affected in such cases. Your data centres located in the UK are best in class, using the most advanced technologies and robust cyber security defences.

Support

Easy Manufacturing implementations are supported by a robust partner eco system across the globe. We also offer a complete managed service that include:

Clientele

Our Reputed Worldwide Partners